Client HD is the largest home improvement retailer in North America, operating 2,300+ stores across the United States, Canada, and Mexico. Wall Panels & Planks is one of its core categories, covering various styles such as wooden Shiplap, Tongue-and-Groove (T&G) planks, 3D decorative panels, and Fluted panels. Serving DIY enthusiasts, professional designers, and contractors, this category generates billions of dollars in annual sales.

Challenges:

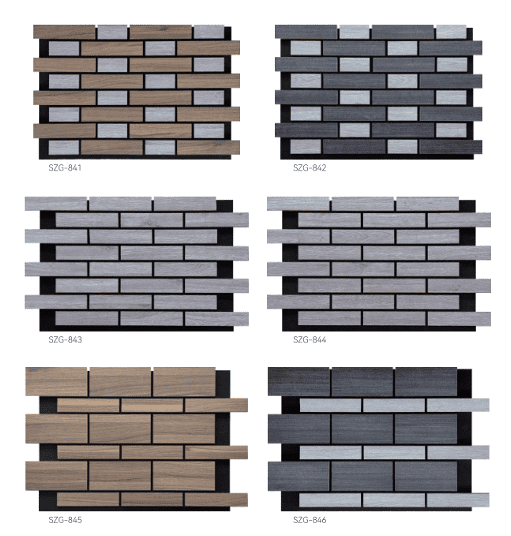

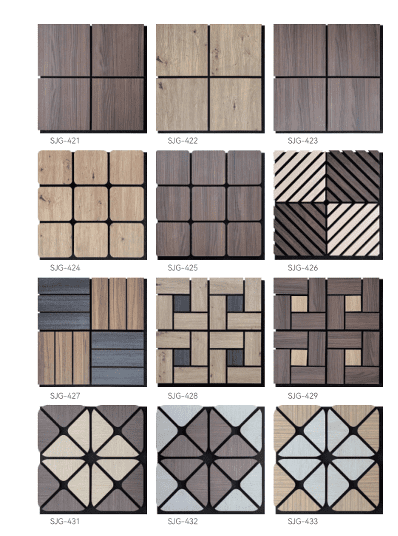

Rapid Iteration of DIY Market Trends: Client HD’s wall panels must follow trends on Pinterest, Instagram, and TikTok (e.g., Rustic Farmhouse, Modern Minimalist, Geometric Diamonds, Fluted). This requires 5–10 new styles per quarter. How can we achieve “Rapid Design Response + Small Batch Trial Production”?

Multi-Process Integration Capability: Wood wall panels involve a complex process chain including wood strip joining, CNC grooving/milling, T&G machining, surface sanding, UV coating, and flatness control. How can these be integrated within a single factory while ensuring stable quality?

Large Panel Transport and Packaging: Large 4×8 foot (1.2m x 2.4m) panels must undergo maritime shipping, inland trucking, and store delivery. How can we ensure zero damage and controlled warping during transport?

Strong R&D Team + PLM Rapid Design:

A dedicated R&D design team was established to continuously monitor North American DIY trends (TikTok trending topics, Pinterest colors, interior designer preferences), launching 50+ market-leading new products annually. Utilizing PLM and 3D design systems, the cycle from conceptual design to sample delivery is compressed to 10 days, supporting Client HD in rapid market feedback testing.

Multi-Process Synergy in Smart Panel Factory:

Introduced specialized automated machinery for panel furniture, including automated joining lines, CNC milling centers, T&G processing lines, wide-belt sanding lines, and automated UV coating/baking lines. The MES system enables intelligent scheduling and standardized process parameters, ensuring joining flatness $\le$ 1mm/m, T&G fit gaps of 0.2–0.5mm, uniform sanding without marks, and UV coating thickness of 80–120μm.

Quality Assurance via Industry-Leading Laboratory:

Established a technologically leading material and product testing lab in China. It covers TSCA Title VI/CARB formaldehyde testing (panels $\le$ 0.09ppm), warpage testing (cup/bow/twist $\le$ 2mm/m), coating abrasion resistance and adhesion, and packaging drop simulations, ensuring products meet North American environmental and quality standards.

Packaging Protection and Logistics Optimization:

Three-layer protection using EPE foam, corner protectors, and moisture-proof film is applied. Large panels are stacked horizontally in layers, with single pallet heights $\le$ 1.5m to avoid pressure deformation. Established container loading standards with Client HD (optimizing space via horizontal/vertical mixed loading) and conducted ISTA 3A packaging tests before shipping to ensure a transport damage rate < 0.5%.

8 Years of Deepened Strategic Cooperation: Growing from an initial trial order of 5 styles in 2017 to over 30 annual delivery styles and a cumulative delivery of 3 million+ square feet of wall panels. We have become Client HD’s core wood wall panel OEM/ODM partner in Asia.

Market-Validated Hits: Jointly developed creative products like diamond-pattern joined panels, pine Fluted panels, and vintage Shiplap planks became DIY trending topics on TikTok and Pinterest. Single-item annual sales exceeded $5 million, and we received the “Outstanding Innovation Supplier” award in 2020 and 2022.

Rapid Trend Capture: The strong R&D team and 10-day sampling cycle support Client HD in capturing trends from TikTok and Pinterest quickly. The cycle from concept to shelf is compressed to 90 days, seizing the initiative in the DIY wall panel market.

One-Stop Supply of Multiple Processes: Integration of wood joining, CNC milling, T&G processing, and UV coating allows Client HD to complete full-category wood wall panel procurement (Shiplap/T&G/Fluted/Diamond blocks) through a single supplier, reducing supply chain management complexity by 30%.

Dual Environmental Certification Assurance: TSCA Title VI/CARB certification combined with our industry-leading laboratory provides environmental and quality assurance that “Made in China = North American Standards.”